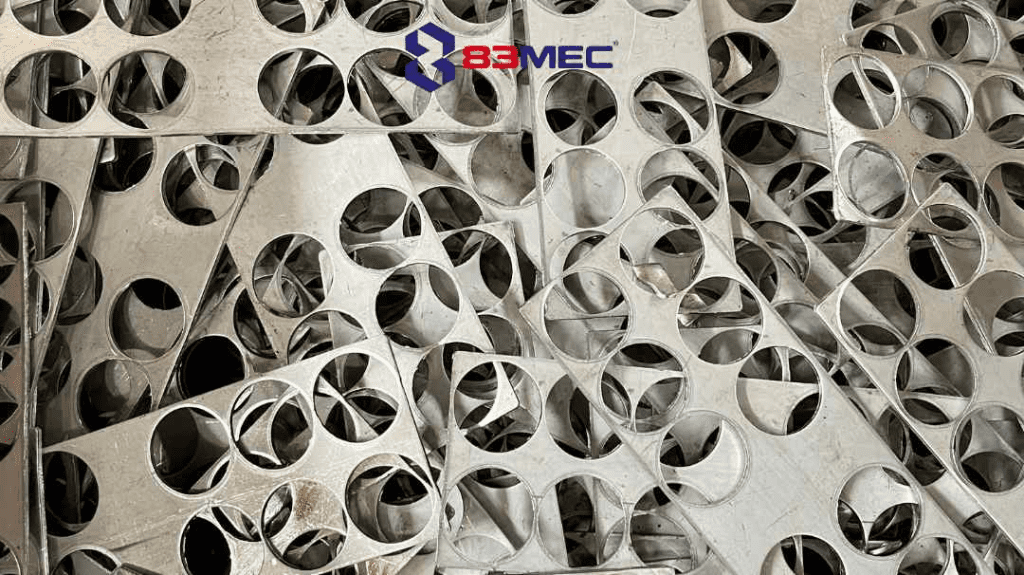

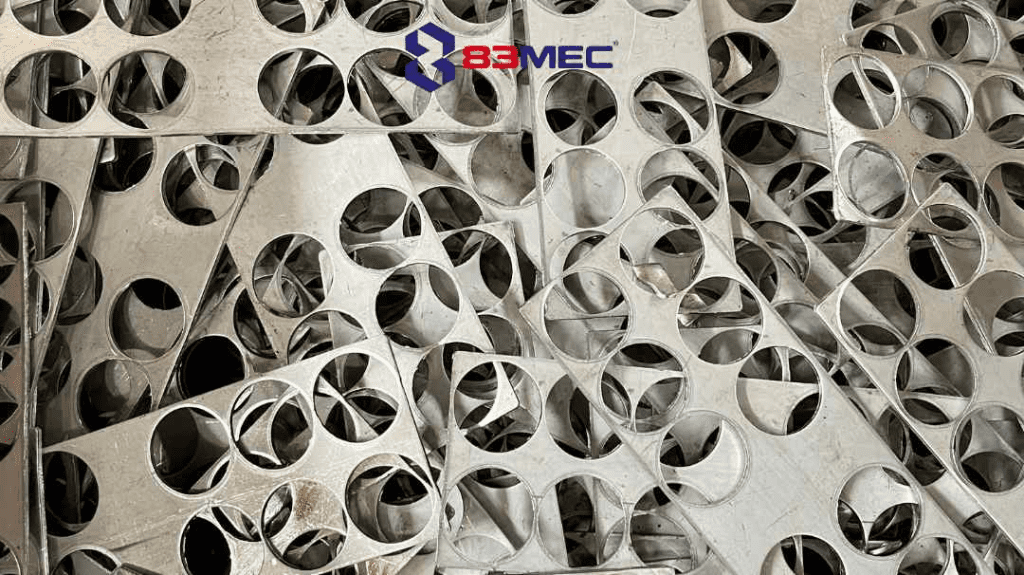

Metal sheet stamping is a crucial process in industrial manufacturing, and at 83MEC, we specialize in providing high-quality solutions for your metal stamping needs. With our state-of-the-art equipment, experienced technicians, and commitment to excellence, we deliver precise and efficient results for various industries.

At 83MEC, we understand the importance of quality in industrial manufacturing. Our metal sheet stamping process is designed to meet the highest standards, ensuring that each stamped component meets your specifications. We work with various materials, including stainless steel, aluminum, copper, and more, catering to diverse industry requirements.

Our skilled technicians utilize advanced stamping machines and computer-controlled systems to achieve exceptional accuracy and repeatability. Whether it’s complex shapes, intricate patterns, or precise cutouts, we can handle your most demanding projects.

We prioritize quality control throughout the metal sheet stamping process to ensure consistent and reliable results. We conduct rigorous inspections at every stage, from material preparation to final inspection, ensuring that each stamped part meets the required tolerances and specifications.

Moreover, we understand the importance of timely production in the industrial sector. Our streamlined processes and efficient workflows allow us to deliver stamped components within your desired timeframe, without compromising quality.

Here is an overview of the metal sheet stamping process at 83MEC:

- Design and Engineering: Our experienced engineers work closely with clients to understand their requirements and design the appropriate stamping tools and dies. We utilize advanced computer-aided design (CAD) software to create accurate and detailed designs.

- Material Selection: We work with various metal sheets, including stainless steel, aluminum, brass, and copper. The choice of material depends on the application and desired characteristics of the final product.

- Tool and Die Preparation: Our skilled technicians fabricate the stamping tools and die according to the specifications once the design is finalized. We ensure the tools are properly maintained and optimized for efficient and precise stamping.

- Material Preparation: The metal sheets undergo cleaning, lubrication, and surface treatment to ensure optimal stamping results.

- Stamping Process: The prepared metal sheets are fed into the stamping press, which combines pressure and controlled movements to deform the material. This process can involve various operations such as blanking, piercing, bending, forming, and embossing.

- Quality Control: We employ strict quality control measures throughout the stamping process to ensure that each stamped component meets the required specifications. We conduct inspections and measurements to verify dimensional accuracy, surface finish, and overall quality.

- Finishing Operations: After stamping, additional finishing operations such as deburring, cleaning, and surface treatments may be applied to enhance the appearance and functionality of the stamped parts.

- Packaging and Delivery: Once the stamped components pass our rigorous quality checks, they are carefully packaged and prepared for delivery to the client. We prioritize safe handling and efficient logistics to ensure prompt delivery.

By choosing 83MEC for your metal sheet stamping needs, you can expect:

- Exceptional Precision: Our advanced equipment and skilled technicians ensure precise and accurate stamping results, even for intricate designs.

- High-Quality Standards: We adhere to strict quality control measures to ensure that each stamped component meets the highest industry standards.

- Customization Options: We work closely with our clients to understand their requirements and provide tailored solutions that meet their needs.

- Timely Delivery: We prioritize efficient production and timely delivery to support your manufacturing schedule.

- Competitive Pricing: Our commitment to providing cost-effective solutions allows us to offer competitive pricing without compromising quality.

Whether you need metal punching for automotive components, electrical enclosures, or any other application, 83 MEC is your trusted partner. Contact us today to discuss your project and experience the precision and quality of our metal punching services.