Products made from sheet metal have become so common today, and to form these products is a meticulous process that not everyone understands. It will be easy to list a product made from metal sheets, from everyday items we often come into contact with and use daily to those used in high-class buildings.

However, listing all products made from metal is complex because metal is ubiquitous in everyday life in many different forms. It can be raw materials, components, equipment, and tools for various industries and fields. And “Sheet metal” attracts many people’s attention; this is a tiny niche in the “metal world”. So what is the sheet metal concept? And what exactly is sheet metal processing technology? Below is helpful information about sheet metal processing that 83MEC wants to share with readers.

I. Overview of sheet metal.

1. What is sheet metal?

Sheet metal is formed into thin, flat pieces, usually by an industrial process. Sheet metal is one of the fundamental forms used in metalworking, and it can be cut and bent into various shapes. They are roughed as raw materials for manufacturing tools, components, equipment, machine parts, household appliances, decorative items, etc. Depending on the starting material of the metal, from iron, steel or aluminum, consider the degree of change after machining, such as hardness, plasticity, bearing, heat resistance, and corrosion resistance.

2. What Is Sheet Metal Fabrication?

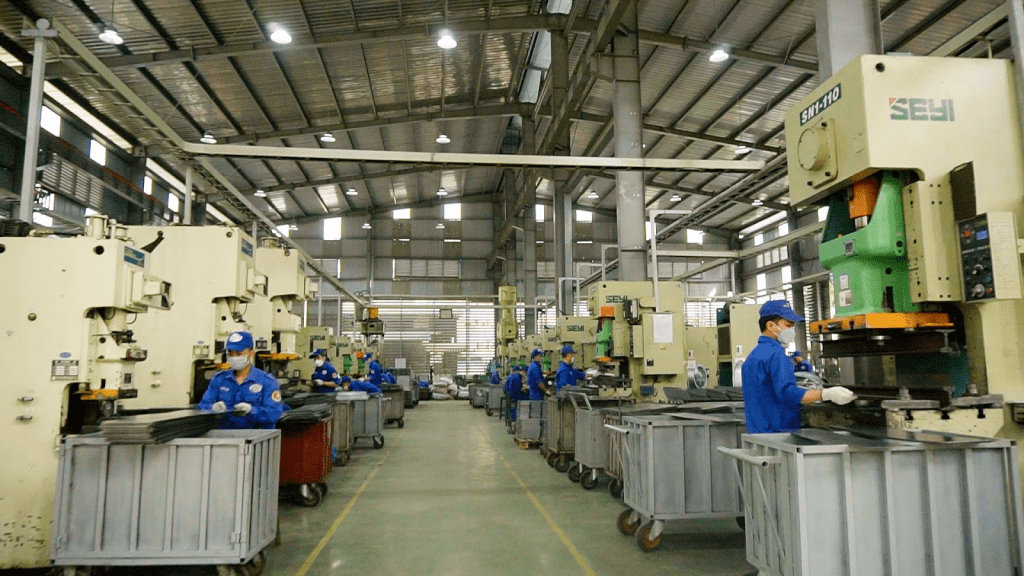

– Sheet metal fabrication is a broad concept, which is the process of selecting and applying options using laser cutting, punching, folding, etc., to affect the original shape of the sheet metal. The sheet metal processing process requires the production team to have technical qualifications and advanced and modern machinery technology to create exact mechanical products.

II. What industries use sheet metal fabrication?

The need for sheet metal fabrication products is increasingly common across many industries and there is no better alternative than sheet metal for those applications. They are flexibly applied in familiar fields such as electronics, medicine, transportation, construction, consumer electronics, agriculture, telecommunications, military, railways, aviation, etc.

The demand of the industries is increasing day by day for the quality of materials and the quality of products after processing. This will accelerate the development of the high-precision sheet metal industry, creating products with minimal tolerances.

Sheet metal processing products are manufactured and classified, including: Commercial, industrial and structural construction.

– For the commercial group, it will be designed and manufactured according to the common criteria of consumers, that is, goods mass-produced and distributed directly to users, such as cabinets, tables, shelves, furniture, and appliances, etc.,

– For the industrial group, it will create parts used to create equipment for other industries, such as cars, motorcycles, food production lines, etc.

– For the group of construction structures will be manufactured on request, such as roofing sheets, billboards, etc.,

III. Advantages of sheet metal machining

– Processing for all different materials: steel, stainless steel, copper, aluminum, plastic,…

– The operation is performed quickly by modern and advanced machining methods.

– High automation, processing on different thicknesses, and complex details, … helps to create a variety of products as required.

– Products with high aesthetics, sharpness, with extremely careful and meticulous cutting lines.

– In particular, using laser machines in processing will help increase productivity and increase competitive advantages by reducing processing costs. Therefore, this is the optimal method trusted by many manufacturers and customers, with advantages in both quality and cost.

IV. Materials used in sheet metal machining.

– Sheet metal machining is usually based on the plasticity of the material. Therefore, materials with high plasticity will be preferred. Specifically iron, steel, and stainless steel;… For specific industries, such as aviation, that need more weight factors, aluminum will be used more. The electrical appliances industry needs to use materials with good electrical conductivity, and then copper will be the choice to be considered.

Above is the basic information about sheet metal processing that 83 MEC wants to share with you. With more than 40 years of experience in the field of mechanical processing, in general, 83MEC specializes in receiving metal processing on request. 83MEC has a large factory system equipped with modern machinery lines such as plasma cutting machines, bending machines, punching machines, hydraulic presses, powder coating systems, … and other specialized machines. Therefore, 83MEC always ensures quality and flexibly responds to customers’ requirements and schedules with competitive costs in the market.